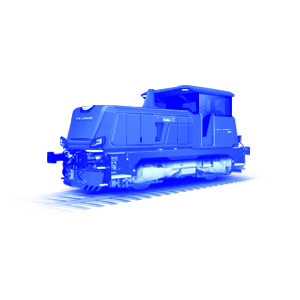

EffiShunter 300

EffiShunter 300

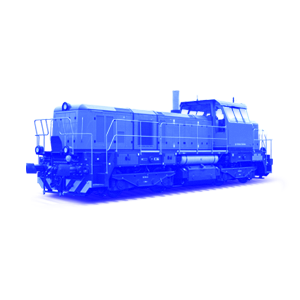

EffiShunter 600

EffiShunter 600

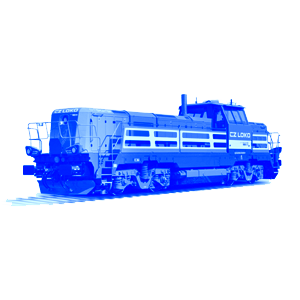

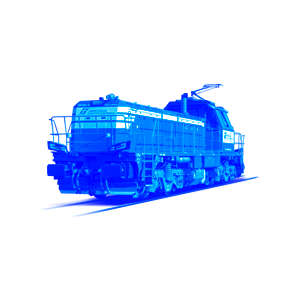

EffiShunter 1000

EffiShunter 1000

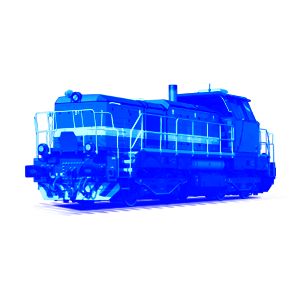

EffiShunter 1000M

EffiShunter 1000M

DualShunter 2000

DualShunter 2000

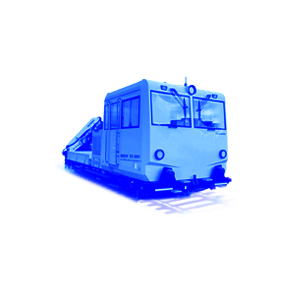

Universal motor truck MUV 75

Universal motor truck MUV 75

EffiShunter 1000 represents the pinnacle of the current development of CZ LOKO. It is designed both for operation on industrial sidings in the most demanding conditions and for line service. For these purposes, it may be equipped with ETCS. Approval according to the internationally recognized TSI certificate guarantees the maximum possible interoperability in the countries of the European Union.

| Track gauge | 1 435 mm/ 1 520 mm |

| Meets the standards | TSI |

| Number of powered axles | 4 |

| Wheelset arrangement | B0' B0' |

| Maximum operating speed | 100 km/h |

| Minimum curve radius | 80 m |

| Line category | C2 |

| Lateral compatibility | 1 |

| Power transmission | electric AC/AC |

| Diesel engine | CAT C32 |

| EU Stage | V |

| Engine output | 895 kW |

| Maximum towing capacity | 262 kN |

| Nominal weight | 80 t |

| Axle load | 20 t |

| Compressor output | 140-252 m3 |

| Fuel tank volume | 4 200 l |

| Climate class | -40 to +40 ºC |

The undercarriage of the locomotive comprises two double-axle bogies with individual drive of all wheelsets. The traction motors are nose-suspended on the axles using rolling bearings. The drive unit is located in the front hood of the locomotive and comprises the Caterpillar diesel engine and the Siemens traction alternator. The front hood space includes most of the auxiliary drives, engine cooling block and the pneumatic unit. The rear hood contains electric switchboards and the electrodynamic brake block. The power regulation and control of the entire locomotive is ensured by the control system made by MSV elektronika with cruise control function and remote diagnostics by means of GSM and GPS technologies. The locomotive is equipped with a DAKO air brake and a parking (stored-energy) brake.